Workshop Descriptions

Barbara will travel to your location to teach workshops on enameling. The following subject categories are examples of how information can be presented. Contact Barbara about creating a workshop focused specifically for the interests of your group.

Getting It Clear! - Transparent Enameling

Learn how to successfully create gorgeous, clear and colorful enameled surface designs using transparent enamels on flat and formed metal while gaining essential information and skills for successful enameling on copper and fine silver.

Combine underglaze black for surface design under TR enamel. Use silver or gold foil and overglaze detailing to increase depth, complexity and color range. Incorporate metal texturing and enamel inlay techniques to create unexpected and individualized detail and interest levels to your enamelwork.

We will focus on how to variety of timeless, versatile and experimental techniques separately and together on flat and formed metal to create diverse results based on your ideas.

We will be combining these techniques with the additional use of TR liquid enamel scrafitto under sifted TR color; layering transparent colors for depth and detail; and using overglaze materials to create detail, definition, depth and increased complextity on flat and formed metal.

Enameling basics will include metals to enamel on, fast and effective methods for cleaning metal prior to enameling, particle size choice, reasons for using graded sifters, grade sifting transparent colors, counter enamel and dry enamel application methods on flat and slightly formed metal. Edge finishing and settings will be discussed and demonstrated.

Students will have time to work on and fire pieces using the various enameling techniques demonstrated. Pieces created in the workshop can serve as examples for future reference or can be suitable for setting with other jewelry techniques and materials.

Combine underglaze black for surface design under TR enamel. Use silver or gold foil and overglaze detailing to increase depth, complexity and color range. Incorporate metal texturing and enamel inlay techniques to create unexpected and individualized detail and interest levels to your enamelwork.

We will focus on how to variety of timeless, versatile and experimental techniques separately and together on flat and formed metal to create diverse results based on your ideas.

We will be combining these techniques with the additional use of TR liquid enamel scrafitto under sifted TR color; layering transparent colors for depth and detail; and using overglaze materials to create detail, definition, depth and increased complextity on flat and formed metal.

Enameling basics will include metals to enamel on, fast and effective methods for cleaning metal prior to enameling, particle size choice, reasons for using graded sifters, grade sifting transparent colors, counter enamel and dry enamel application methods on flat and slightly formed metal. Edge finishing and settings will be discussed and demonstrated.

Students will have time to work on and fire pieces using the various enameling techniques demonstrated. Pieces created in the workshop can serve as examples for future reference or can be suitable for setting with other jewelry techniques and materials.

Settings: Beyond the Bezel

There will be discussion, demonstrations and exploration of possibilites for combining and setting enamel pieces in jewelry or objects. The possibilities are endless and range from traditional bezel setting to use of gold twist ties and everything in-between. The main goal will be to figure out and learn how to accomplish the best settings for the desired results according to individual criteria.

Participants will figure out WHAT is most important when setting their enamel piece and then HOW to accomplish their goals.

- Do you want to be able to “fix” a piece (later) easily without destroying the “setting”?

- Should the setting be as “inconspicuous” as possible? Or is the setting a focus?

- Will the edges of the enamel be visible or hidden?

- Are set stones included in the piece? Next to or on top of the enamel?

- Is the setting an important or integrated part of the design of the piece?

- Do you figure out the setting before the enamel is done? Or after?

- What is the “order of making” for the entire piece?

- Are you “opposed” to using 21stcentury “chemical bonding” – a.k.a. epoxy glue?

- Setting options include–but are not limited to–layered sheet setting, tab setting variations, twist ties from precious metal wire, rivets, mini nuts/bolts, epoxy, bezels, frames and more.

We will look closely at many examples. It is hoped participants will also bring setting examples. After discussion and demonstrations, participants will be able to choose the most suitable method(s) for setting their pieces – or - the setting that arouses the most curiosity and has the most potential.

Participants will figure out WHAT is most important when setting their enamel piece and then HOW to accomplish their goals.

- Do you want to be able to “fix” a piece (later) easily without destroying the “setting”?

- Should the setting be as “inconspicuous” as possible? Or is the setting a focus?

- Will the edges of the enamel be visible or hidden?

- Are set stones included in the piece? Next to or on top of the enamel?

- Is the setting an important or integrated part of the design of the piece?

- Do you figure out the setting before the enamel is done? Or after?

- What is the “order of making” for the entire piece?

- Are you “opposed” to using 21stcentury “chemical bonding” – a.k.a. epoxy glue?

- Setting options include–but are not limited to–layered sheet setting, tab setting variations, twist ties from precious metal wire, rivets, mini nuts/bolts, epoxy, bezels, frames and more.

We will look closely at many examples. It is hoped participants will also bring setting examples. After discussion and demonstrations, participants will be able to choose the most suitable method(s) for setting their pieces – or - the setting that arouses the most curiosity and has the most potential.

Forms Enameled!!! Using Copper Sheet and Screen with Liquid and Powdered Enamels

Learn to enamel a variety of 3D forms.

We will work with the basics of dipped and sprayed applications of liquid enamel in combination with and separate from sifted applications of powdered enamel on a wide variety of forms that range in size/function from objects to jewelry. Objects to enamel can be formed jewelry pieces and pre-formed purchased copper or pre-enameled steel “camp ware”. Pre-formed pieces allow participants to learn application methods of spraying/dipping/sifting on a 3D form without having to “make” the form first. Participants can also bring copper 3D forms that they have made via methods of their choice - such as raised, dapped, fold formed, die formed, repoussed, etc. Demonstrations will include forming and enameling copper screen, thin copper sheet and wire to create jewelry forms or objects. Gold and silver foil and leaf application on 3D forms will allow for the addition of decorative detail.

We will work with the basics of dipped and sprayed applications of liquid enamel in combination with and separate from sifted applications of powdered enamel on a wide variety of forms that range in size/function from objects to jewelry. Objects to enamel can be formed jewelry pieces and pre-formed purchased copper or pre-enameled steel “camp ware”. Pre-formed pieces allow participants to learn application methods of spraying/dipping/sifting on a 3D form without having to “make” the form first. Participants can also bring copper 3D forms that they have made via methods of their choice - such as raised, dapped, fold formed, die formed, repoussed, etc. Demonstrations will include forming and enameling copper screen, thin copper sheet and wire to create jewelry forms or objects. Gold and silver foil and leaf application on 3D forms will allow for the addition of decorative detail.

Enameling: Have It Your Own Experimental Way: Subtle Surfaces, Bold Marks, Inlay, Foils, Screen & more.

Emphasis on exploration and experimentation with traditional and non-traditional enameling techniques with the intent of achieving exciting surfaces that exceed expected results. Participants will gain a thorough understanding of enameling basics when using sifted applications along with other methods for creating exciting embellished enameled surfaces in a variety of unexpected ways. The techniques offered for participants to explore include, but are probably not limited to - use of copper oxide, copper fillings, inlay techniques, drawing with graphite or metals, scrafitto using iron oxide or 200 mesh enamels, application and firing of vintage/solid color/gold and laser printed decals; painting enamels for detail, uses/combinations of gold/silver foil application, using corrugated metal; creating the illusion of a textural surfaces and more.

Enameling: The Basics and Some Fun Stuff!!

Learn the essential information about enamel preparation and application and skills necessary for becoming confident and successful with enameling using a kiln. Many of the misconceptions about kiln firing enameling will be dispelled. A variety of fun techniques for creating a complex and colorful enameled surfaces, quickly and easily, on flat or formed metal will be demonstrated.

Colorful, Exciting Surface Designs Using Opaque Enamels

Learn inspiring, decorative techniques that quickly yield colorful, exciting and complex enameled surface designs while gaining basic information and skills for successful enameling. Decorative techniques include scrafitto, found and made stencils. using rubber stamps and dry screen printing enamel powder.

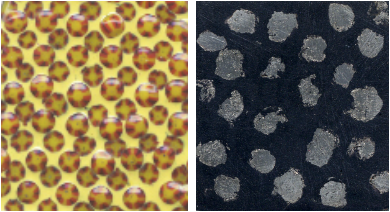

Luscious Surface Designs with Depth using Transparent Enamels

Create luscious, glowing enameled surfaces using transparent enamels in combination with smooth or textured copper, underglaze black and silver and gold foil. Learn how to prepare and fire transparent enamels for maximum clarity when used with a sifted application.

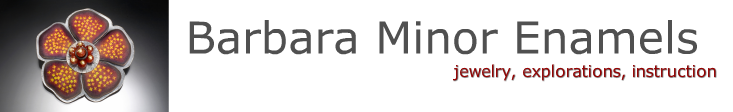

Experimental Enamel Surfaces: Inlay Techniques

Emphasis is on exploration and experimentation with traditional and non-traditional enameling techniques with the intent of achieving exciting surfaces that exceed expected results. A variety of techniques are offered to the host venue to choose from for this workshop. Pictured at the left is "seed bead inlay" and "silver spit ball inlay". Please contact Barbara for more possibilities and specifics.

Enameling: Subtle Surfaces and Bold Marks

Learn the basics of enameling, sifted and dipped enamel application and how to embellish enamel surfaces using painting enamels, enamel crayons, graphite and enamel pencils, ceramic oxides and atomized metals. Techniques to accomplish your own images and designs include sifted and dipped enamel application, use of a variety of over and underglaze materials, scrafitto, stenciling, making/use of decals and mixing and altering painting enamel colors.

Form in Screen: Liquid and Sifted Enamels

Work with the ever so pliable copper screening to achieve a wide variety of forms from vessels to beads. Then apply liquid and sifted enamel colors to create colorful results. Along with enameling basics, students will learn how to form the screen and apply the liquid and sifted enamels.

Enameling and Decals - Making/Application/Firing

Learn the basics of enamel application and embellish the enamel surfaces with a variety of decal products suitable for firing on vitreous enamel. Use luster decals for patterned designs. Make iron oxide decals of designs you choose. Learn to work with a variety of commercially available image-type decals.

Embossed Foil and Transparent Enamels

Work with transparent enamels and embossed silver foil to create amazingly detailed enameled surfaces with just a few colors. Students will learn how to emboss and enamel the foil as well as how to make the embossing plates. Students will learn how to prepare and fire transparent enamels for maximum clarity when used with a sifted application.

All instructional workshops includes in depth information about the fundamentals of enameling and metal preparation while also allowing time for the students to work with the techniques demonstrated. The goal is for students to leave a workshop feeling confident that they can work with the new processes on their own in their personal studios.

All workshops allow for students to work their own copper shapes or with a wide variety of shapes provided by Barbara.

Workshop subject matter can always be adjusted to meet the needs of your group.

Contact Barbara for more information about traveling to your location to teach, teaching fees, questions about materials, availability and subject matter.

All workshops allow for students to work their own copper shapes or with a wide variety of shapes provided by Barbara.

Workshop subject matter can always be adjusted to meet the needs of your group.

Contact Barbara for more information about traveling to your location to teach, teaching fees, questions about materials, availability and subject matter.